Unified Distribution Control

Run the entire enterprise from a single app with command of fulfilment, labour, slotting, and automation.

Global Visibility

Manhattan Active® WM offers a single view of inventory, from inbound to DC, on yard, reserve storage, active pick sites, automated storage, and all the way through outbound shipments. Learn More

Facility-Level Visibility

Manhattan's WMS software allows you to see the facility’s overall inbound and outbound—along with individual, departmental, and overall performance against goals.

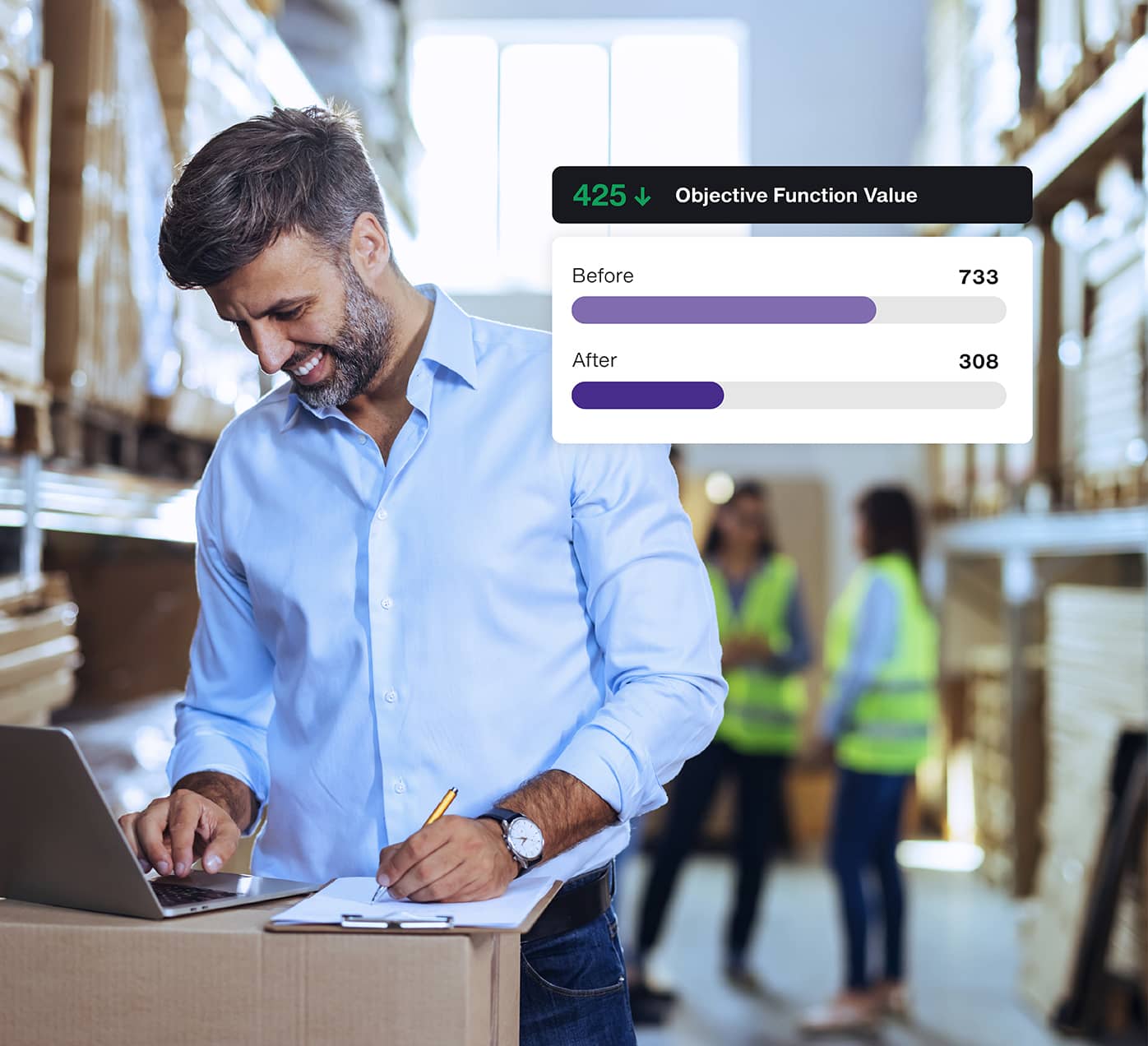

Actionable Insights

See real-time performance for your entire supply chain—or just one facility. Identify areas showing less-than-expected performance with a single tap.

Digital Twins

Manhattan’s WMS system allows you to see an employee or resource in a digital representation of the warehouse—and react with people, equipment, and tasks in real time.

Unified Planning

Optimise order fulfilment with machine learning that maximises efficiency, productivity, and profitability—while simultaneously processing retail, wholesale, and direct demand.

Order Streaming

Leverage intelligent, automated resource orchestration with a system that adjusts to new orders, labour changes, equipment failures, and more—keeping the facility at maximum utilisation.

Execution-Driven Planning

As workers and machines execute tasks, Order Streaming records each action—over time it anticipates how long a task will take based on factors like number of stops, distance travelled, location, and time.

Adaptive Work Planning

Regulate the pace and amount of work—selectively delaying some fulfilment decisions, while taking advantage of execution feedback or changes in the order pool.

Smart Task Execution

Create and modify pick paths in real time—using machine learning to accommodate worker decisions.

Unified Execution

Eliminate barriers to efficiency like 'pick type' and 'order type' by orchestrating put-away, picking, slotting, sorting, and packing activities simultaneously.

Dynamic Workflow

Set up dynamic workflows with configuration wizards that adjust to match real-time operations.

Engaged Experiences

Logistics capabilities are unified in a single app, which means less training for users, more visibility and control for supervisors, and intuitive workflows with configurable instructions, images, and actions.

Optimised Slotting

Integrate slot and re-slot into put away and picking workflows.

Targeted Support

Support for hundreds of needs—lot management, perishable fast flow, load stop sequencing and more—across industries like retail, apparel, footwear, direct-to-consumer, food, grocery, 3PL, life sciences, and high tech electronics.

Unified Automation

Use technology to your advantage to simplify the process and save time.

Robot-Ready

Use machine learning to optimise fulfilment across advanced automation, robotics, and human associates.

Person and Machine in Sync

Get maximum throughput when every asset (automation, robotics, people) works together.

WES Inside WMS

Manhattan Active WM's software integrates advanced material handling equipment, such as sortation equipment, put walls, and automated storage and retrieval, as well as the latest robotic solutions.

Manhattan Automation Network

Make it easy to onboard automation technology by building base integrations and pretesting them collaboratively.